We are Manufacturer, Supplier, Exporter of Intensive Sand Mixers For Sand Plant, Sand Preparation Equipments. Our setup is situated in Kolhapur, Maharashtra, India. Majorly we serve customers from African, Gulf countries and all over India.

| MODEL | IM-250VE | IM-300VE | IM-500VE | IM-750VE | IM-1000VE |

| Batch Capacity (kg) | 250 | 300 | 500 | 750 | 1000 |

| Diameter of shell (mm) | 1260 | 1360 | 1600 | 1750 | 1975 |

| Total Height with batch(mm) | 2150 | 2400 | 2700 | 2900 | 3200 |

| Width & length (mm) | 1488 X 1220 | 1505 X 1640 | 2340 X 1920 | 2620 X 2110 | 2900 X 2250 |

| Drive for Mixing Blade (HP) | 10 | 15 | 50 | 75 | 100 |

| Drive for Blander Blade (HP) | 5 | 7.5 | 20 | 30 | 40 |

| Model | CSM-50VE | CM-100VE | CM-150VE | CM-250VE | CM-300VE | CM-500VE |

| Batch Capacity (kg) | 50 | 100 | 150 | 250 | 300 | 500 |

| Diameter of shell (mm) | 555 | 815 | 1000 | 1260 | 1360 | 1600 |

| Total Height (mm) | 772 | 1182 | 1258 | 1390 | 1428 | 2062 |

| Drive for Mixing Blade (HP) | 5 | 5 | 7.5 | 10 | 15 | 30 |

| MODEL | RCM-300VE | RCM-500VE | RCM-800VE |

| Batch Capacity (kg) | 300 | 500 | 800 |

| Diameter of shell (mm) | 1260 | 1400 | 1600 |

| Total Height (mm) | 2660 | 2930 | 3025 |

| Drive for Mixing Blade (HP) | 20 | 50 | 75 |

| MODEL | CM-005VE | CM-008VE | CM-010VE |

| Batch Capacity (TPH) | 5 TO 8 | 10 TO 12 | 15 TO 20 |

| Mixer motor (HP) | 7.5 | 10 | 15 |

| Hardener pump (HP) | 0.5 | 0.5 | 0.5 |

| Resin pump (HP) | 0.5 | 0.5 | 0.5 |

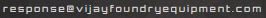

| MODEL | SD-03VE | SD-05VE | CM-08VE |

| Batch Capacity (TPH) | 1.5 TO 3 | 3 TO 5 | 5 TO 8 |

| Motor (HP) | 3 | 5 | 7.5 |

| H X W X L (m) | 2.1 X 1.5 X 4.5 | 3.6 X 3.5 X 7.5 | 3.6 X 3.5 X 9.5 |

| No. Of Drums | Double | Double | Double |

| Fuel to be used | Diesel,LDO,GAS | Diesel,LDO,GAS | Diesel,LDO,GAS |

| Moisture after Drying | 0.5% | 0.50% | 0.50% |

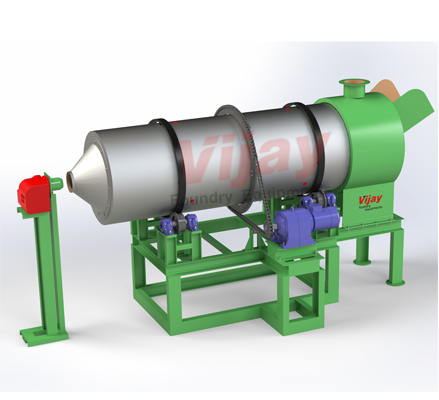

Now a days, the sand price is considerable amount while calculating the production cost per kg of casting & weight, & it also plays part during the production. Normally sand is divided in three major particles, first one is dust, second one is heavy particles and the third is useful particles whose size is between first & second. The Sand Lump Breakers are useful to break small and big sand lumps which are separated from mould box after poured casting. Vibratory motion breaks the lump in small particles which are screened by various screens and finally they come out in total three discharge outlet viz. dust, heavy particles and useful sand between dust & heavy particles. This reclaimed sand is useful as a backing sand to save the quantum of fresh sand used in every month. It will save production cost with minimum floor space, electric power, man power and maintenance.

- Very useful to reclaim the CO2 sand lumps.

- Up to 80% reclaimed sand can be used as a supporting while moulding.

- Reduction in the percentage of Sodium Silicate.

- Breaking takes place by high speed rotors.

- The Rotors blades are lined with high wear resistant material

- Low maintenance cost.

- 3 Tons/Hrs.

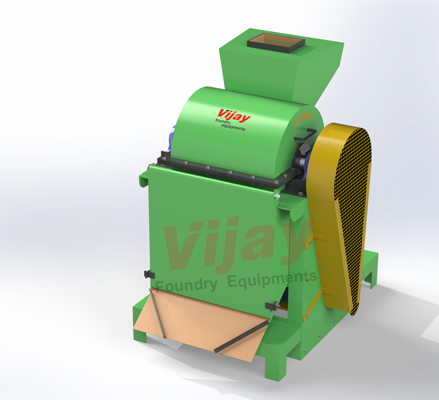

Our Sand Siever to sieve the return and fresh sand in very essential in medium and small foundry for sieving sand driven with suitable drive.

- 5 Tons / Hrs.