We are Manufacturer, Supplier and Exporter of Foundry Dust Collection System, Foundry Dust Collector, Dust Collector System, Industrial Dust Collector System, Outdoor Dust Collector System, Dust Collectors for Foundry Applications. Our setup is situated in Kolhapur, Maharashtra and majorly we serve our customers from African, Gulf countries and all over India.

A dust collector is a system used to enhance the quality of air released from industrial and commercial processes by collecting dust and other impurities from air. Designed to handle high-volume dust loads, a dust collector system consists of a blower, dust filter, a filter-cleaning system, and a dust removal system. It is distinguished from air cleaners, which use disposable filters to remove dust. Our Dust Collector is work on the pulse jet principle.

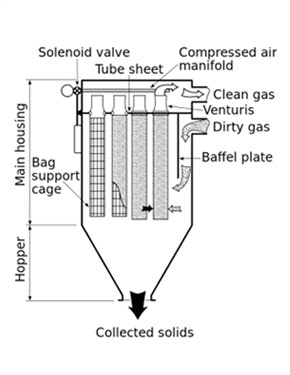

In reverse-pulse-jet bag houses, individual bags are supported by a metal cage (filter cage), which is fastened onto a cell plate at the top of the bag house. Dirty gas enters from the bottom of the bag house and flows from outside to inside the bags. The metal cage prevents collapse of the bag. Bags are cleaned by a short burst of compressed air injected through a common manifold over a row of bags. The compressed air is accelerated by a venturi nozzle mounted at the reverse-jet bag house top of the bag. Since the duration of the compressed-air burst is short (1-2 s), it acts as a rapidly moving air bubble, traveling through the entire length of the bag and causing the bag surfaces to flex. This flexing of the bags breaks the dust cake, and the dislodged dust falls into a storage hopper below. The short cleaning cycle of reverse-jet collectors reduces recirculation and redeposit of dust. These collectors provide more complete cleaning and reconditioning of bags than shaker or reverse-air cleaning methods. Also, the continuous-cleaning feature allows them to operate at higher air-to-cloth ratios, so the space requirements are lower.

- Have high air to cloth ratio (6 to 10 ft. /min.)

- Have high collection efficiency for respirable dust

- Have lower bag wear

- Clean continuously

- Long service life