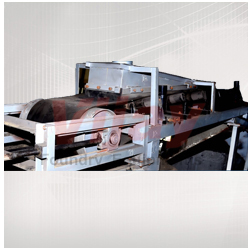

| MODEL | FVC-10VE | FVC-15VE | FVC-20VE | FVC-30VE | FVC-40VE |

| Capacity (TPH) | 10 | 15 | 20 | 30 | 40 |

| Length X Width (mm) | 4000 X 650 | 4000 X 850 | 4000 X 1000 | 5000 X 1000 | 5000 X 1200 |

| Vibro Power (HP) | 12 | 20 | 30 | 38 | 47 |

| Fluidisation Fan Power (HP) | |||||

| Rotary Air Lock(HP) |

| MODEL | IM-250VE | IM-300VE | IM-500VE | IM-750VE | IM-1000VE |

| Batch Capacity (kg) | 250 | 300 | 500 | 750 | 1000 |

| Diameter of shell (mm) | 1260 | 1360 | 1600 | 1750 | 1975 |

| Total Height with batch(mm) | 2150 | 2400 | 2700 | 2900 | 3200 |

| Width & length (mm) | 1488 X 1220 | 1505 X 1640 | 2340 X 1920 | 2620 X 2110 | 2900 X 2250 |

| Drive for Mixing Blade (HP) | 10 | 15 | 50 | 75 | 100 |

| Drive for Blander Blade (HP) | 5 | 7.5 | 20 | 30 | 40 |

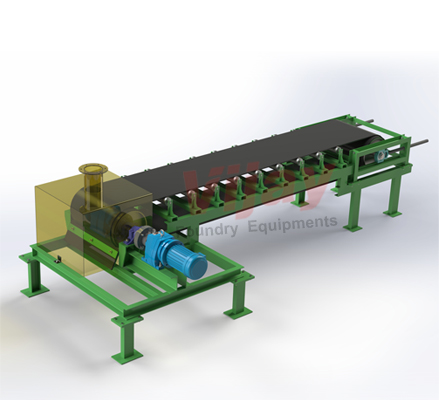

| MODEL | PS-20VE | PS-40VE |

| Capacity (TPH) | 20 | 40 |

| Total Height (mm) | 1835 | 2700 |

| L X W (mm) | 4126 X 1600 | 4800 X 2500 |

| Drive Motor (HP) | 5 | 10 |

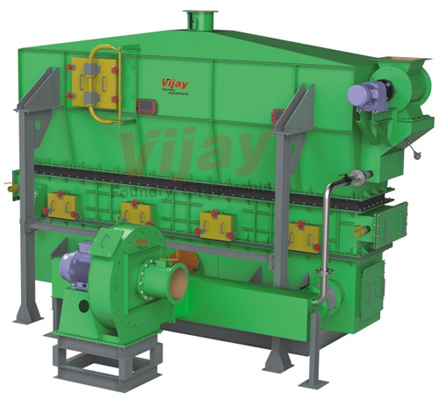

Bucket Elevators

| MODEL | BE-10VE | BE-20VE | BE-40VE |

| Capacity (TPH) | 10 | 20 | 40 |

| Total Height (mm) | As per required | As per required | As per required |

| L X W (mm) | 750 X 375 | 1070 X 555 | 1280 X 645 |

| Drive Motor (HP) | As per height | As per height | As per height |

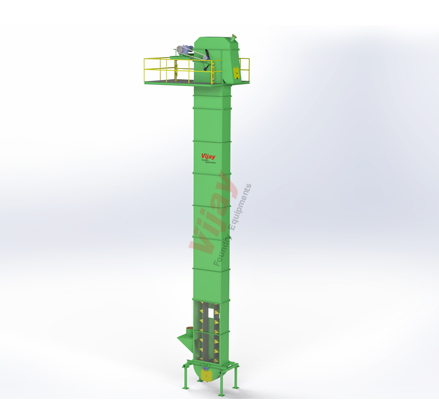

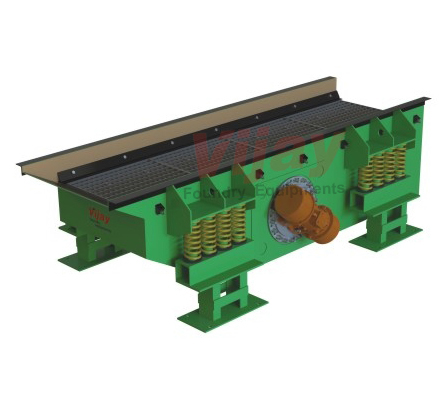

| MODEL | VESVK 01 | VESVK 02 | VESVK 03 | VESVK 04 |

| Grid Size (mm) | 1000 X 1200 | 1000 X 1500 | 1000 X 3000 | 1000 X 4000 |

| Elecetic Motor (Kw) | 0.75 X 2 | 1.3 X 2 | 1.8 X 2 | 2.2 X 2 |

This is another type of knockout machine. This is simple and robust machine designed for continuous duty to separate castings from sand, cores from castings & feed sand from one place to another place. It consist of top frame made of number of Flats, two vibro motors, Main body, Feeder Trough & the base frame is specially designed to withstand heavy shots and overload. The main body is supported on a sets of coil springs, which is designed in such a way that it will transmit very less vibration effect to the base frame. The trough Vibrates with higher efficiency, which is constant over the entire area, which gives the maximum achievable capacity. Due to the vibration produced the sand particle will move from its place and it will discharge to hopper.

- High Precision

- Sturdy

- Energy efficient

- Long service life

500 kg To 20000 kg & 3 Meter To 6 Meter

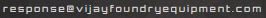

- Vibrating feeder is used for travelling of hot sand. We produce vibrating feeder upto 6 meter length.

Belt conveyors were created for use in foundries under severe working condition, where both high productivity and the long plant running time, require great machine efficiency. Product is conveyed directly on the belt so both regular and irregular shaped objects, large or small, light and heavy, can be transported successfully. Belt conveyors can be used to transport product in a straight line or through changes in elevation or direction. A Belt Conveyors consists of a body of a metal frame with pulleys at either end or bed of rollers in between. Belt is looped around each pulley's. When one of the belt is powered by electrical motor, the belting slides across the rollers there by moving the product on the top of the belt.

- Low maintenance

- Robust construction

- Easy to install

- Durable

- Endure operational temperature

- No spillage of sand

- Continuous duty

Range : 5 to 40 Ton / hr

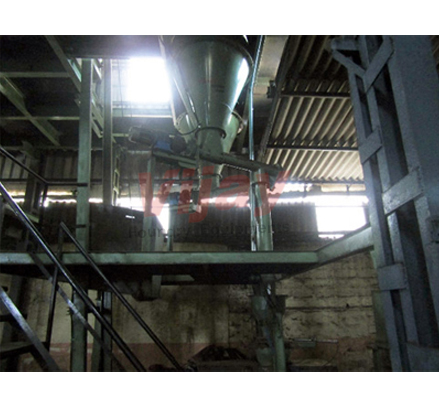

We offer our clients with an extensive range of Sand storage Hopper which is manufactured as per the quality standards of the industry. Sand storage hopper is used to store the sand in large capacity. This hoppers are used for fresh sand storage, moulding sand storage, for return sand storage etc. This hopper is fabricated from MS channels, angles & plates. To avoid choking & to give the free movement the uniflow arrangement is made in the bottom of hopper also a cone shaped fabricated part is mounted on inside hopper. Which will carry the total sand load & it will guide the sand to move freely. All our industrial storage hoppers are available in different capacities and are provided to our clients as per their specific requirements.

- Low maintenance

- Robust construction

- Durablee

Range : 5 To 100 Tons.

This system is basically used in green sand plants.

- Screw conveyor

- Hopper

- Load cell system

This system is handelled by plc control. Bentonite addition system contains Two hoppers one for bentonite storage and another for coal powder Storage. Screw conveyor decides how much powder percentage is required And finally the load cell discharges calculated amount of material.

- We use automatic plc control system in which no need of human Effort.

- Automatic plc system inhances the quality of sand combination.

- Once hoppers are filled with material then it is sufficient for whole Day.