| SIZE (mm) | MOTOR (KW) | OUTPUT (TON/HR) | LOAD (KG) |

| 1200 X 1285 | 2.2 X 2 | 5 | 1000 |

| 1500 X 1500 | 3.6 X 2 | 7 | 1400 |

| 2000 X 2000 | 5 X 2 | 11 | 2500 |

| MODEL | HORIZONTAL PARTING | VARTICAL PARTING |

| Core Capacity (Kg) | 1-10 Kg. | 1-10 Kg. |

| Core box size (l*b*h) | 550X550X300 | 550X550X300 |

| Cycle time per / core (min.) | 1 | 1 |

| Core removing stroke (mm) | 300 | 300 |

| Shooting sand air pressure (bar) | 7 | 7 |

| Air consumption per/core (Cfm) | 22-30 | 22-30 |

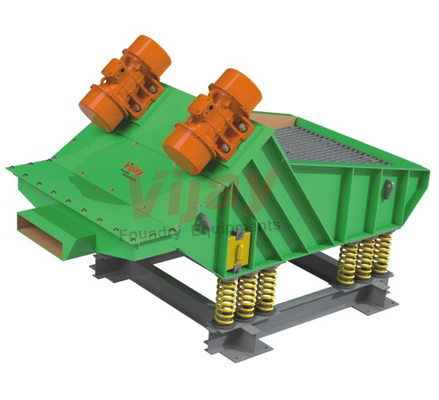

| Comparison Manual Lining V/S Lining Using Vibrator | ||

Sr. No. |

Manual Lining |

Using Lining Vibrator |

1) |

Lining life is inconsistence & shorter. |

Consistent and improve lining life |

2) |

Unpredictable production |

Predictable and increased total output tonnage |

3) |

Density of Lining is not uniform throughout the shell. |

Density of lining is uniform throughout the shell. |

4) |

Lining thickness is not uniform throughout the shell. |

Lining thickness is uniform throughout the shell. |

5) |

Lots of hazardous silica & dust in the air |

Pollution free |

6) |

whole process is time consuming |

Whole process of lining is completed in 2-3 hours. |

7) |

Trouble due to human component like attitude, error & fatigue. |

Smooth and trouble free operation |

| Machine Model : | ||

| SM Model | Capacity (Furnace) | Vibrator |

| VE LV 01 | 500 Kg-1.5 TON | 2 Arm Vibrator |

This is very popular in small and large foundries due to flexibility of shifting at any place. The minimum force is required for lifting due to special lever type design. Pin lift hand moulding machine is rigid in construction and easy in operation.

- Robust Construction

- Durable

- Low maintenance costs

- Easy to operate

- Long service life

Range : 6" & 8".