We are Manufacturer, Supplier, Exporter of Intensive Sand Mixers For Sand Plant, Sand Preparation Equipments. Our setup is situated in Kolhapur, Maharashtra, India. Majorly we serve customers from African, Gulf countries and all over India.

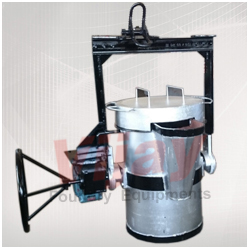

For lip pour design the ladle is tilted and the molten metal pours out of the ladle like water from a pitcher. The bail arm is strong enough to withstand heat & load for years together without any distortion. Vent holes are provided to remove gases. A locking device is provided to keep the ladle vertical during handling. Gear box is provided for easy tilting of the ladle while pouring. Ladle can be designed as per customer requirement.

- Consistent performance

- Robustness

- Lower temperature losses

- Safer ladle operation

- Ease of ladle operation

Range 150 Kg-10 ton

The teapot spout design, like a teapot, takes liquid from the base of the ladle and pours it out via a teapot spout. Any impurities in the molten metal will form on the top of the metal so by taking the metal from the base of the ladle, the impurities are not poured into the mould. The bail arm is strong enough to withstand heat & load for years together without any distortion. Vent holes are provided to remove gases. A locking device is provided to keep the ladle vertical during handling. Gear box is provided for easy tilting of the ladle while pouring. Ladle can be designed as per customer requirement.

- Consistent performance

- Robustness

- Lower temperature losses

- Safer ladle operation

- Ease of ladle operation

Range 150 Kg - 2 ton

Bottom pouring ladles are used for Steel Casting. For bottom pour ladles, a stopper rod is inserted into a tapping hole in the bottom of the ladle. To pour metal the stopper is raised vertically to allow the metal to flow out the bottom of the ladle. To stop pouring the stopper rod is inserted back into the drain hole. Any impurities in the molten metal will form on the top of the metal so by taking the metal from the base of the ladle, the impurities are not poured into the mould. The bail arm is strong enough to withstand heat & load for years together without any distortion. Vent holes are provided to remove gases. A locking device is provided to keep the ladle vertical during handling. Gear box is provided for easy tilting of the ladle while pouring. Ladle can be designed as per customer requirement.

- Quick and simple erection

- Precision engineered

- Consistent performance

- Robustness

- Lower temperature losses

- Safer ladle operation

- Ease of ladle operation

Range 500 Kg-10 ton

A ladle used for a process to take place within the ladle to change some aspect of the molten metal. A typical example being to convert cast iron to ductile iron by the addition of various elements into the ladle. The bail arm is strong enough to withstand heat & load for years together without any distortion. Vent holes are provided to remove gases. A locking device is provided to keep the ladle vertical during handling. Gear box is provided for easy tilting of the ladle while pouring. Ladle can be designed as per customer requirement.

Range 150 Kg-10 ton

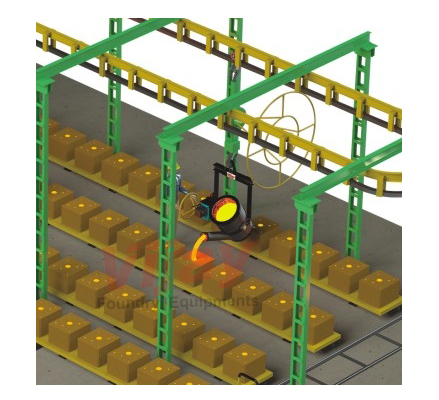

We are Manufacturer, Supplier, Exporter of Foundry Monorail and Crane System, Foundry Overhead Crane, Foundry Crane, Foundry Equipment, Foundry Crane, Metallurgy Crane Crane Monorail System in Modern Foundries. Our setup is situated in Kolhapur, Maharashtra, India. Majorly we serve customers from African, Gulf countries and all over India.

- Monorails are used for Laddle Tranfer. We make Heavy Duty and High Quality Monorail.

- Full Cupola Drum with foundation frame.

- Direct Cupola charger.

- Wet scrubber (pollution control unit).

- Stack Monitoring Platform for pollution Board.

- Blower with dusting.