We are Manufacturer, Supplier and Exporter of Sand Dryer, Sand Dryer Machine, Diesel Fire Type Sand Dryers. Our setup is situated in Kolhapur, Maharashtra, India. Majorly we serve customers from African, Gulf countries and all over India.

| MODEL | SD-03VE | SD-05VE | CM-08VE |

| Batch Capacity (TPH) | 1.5 TO 3 | 3 TO 5 | 5 TO 8 |

| Motor (HP) | 3 | 5 | 7.5 |

| H X W X L (m) | 2.1 X 1.5 X 4.5 | 3.6 X 3.5 X 7.5 | 3.6 X 3.5 X 9.5 |

| No. Of Drums | Double | Double | Double |

| Fuel to be used | Diesel,LDO,GAS | Diesel,LDO,GAS | Diesel,LDO,GAS |

| Moisture after Drying | 0.5% | 0.50% | 0.50% |

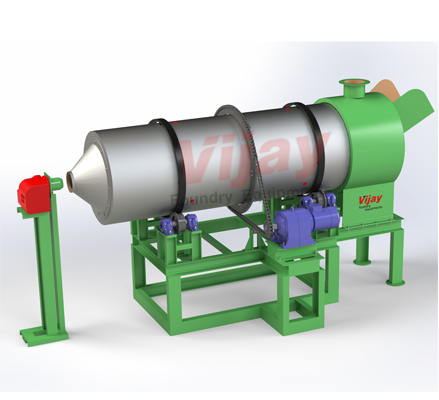

The dryer is employed to reduce or minimize the liquid moisture content of the material it is handling by bringing it into direct contact with a heated gas. The dryer is made up of a large, rotating cylindrical tube, usually supported by steel beams. Material to be dried enters the dryer, and as the dryer rotates, the material is lifted up by a series of internal fins lining the inner wall of the dryer. When the material gets high enough to roll back off the fins, it falls back down to the bottom of the dryer, passing through the hot gas stream as it falls. This gas stream can either be moving toward the discharge end from the feed end, or toward the feed end from the discharge end. The gas stream can be made up of a mixture of air and combustion gases from a burner.

Our Sand Dryer is of double drum double pass type, specially designed to dry foundry sand, complete with Burner, drive unit for the Dryer rotation, galvanized sheet with glass-wool for avoiding heat transfer, integral base also having Special scoop feeding system is provided for charging the Dryer from a lower height. We also provide Auto cycle Control Panel as per requirement.

- Double Shell Double Pass Type

- Robust Construction

- Low Noise

- Short Drying time

- Energy Efficient

- Designed for continuous operation

- High performance centrifugal fan

- Very Compact Design

- Precise Control of flame

- Adjustable Combustion Head & easy accessible

- Automatic Air Gate closing

- Less oil consumption

- Less carbon deposition hence Low maintenance

- Easy Maintenance of burner, without removing from the drier

- Low Noise

- Low or No Back pressure

- No Leakage in burner after turn-off